Digital Twin

Digital Twin

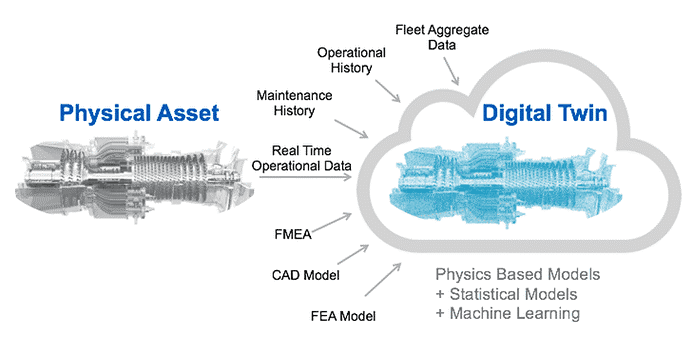

The use of digital twins enables you to foresee probable future issues. Along with other benefits, this decreases product faults and speeds up manufacturing.

By optimizing Digital Twin, performing preventive maintenance tasks can lower maintenance costs. Using real information can also be used to improve and optimize production operations. The digital twin is a fantastic tool that enables you to imitate behaviors and lower risks while testing new technologies online.

Additionally, they let you optimize the actions and states that take place while monitoring activities in real-time. With minimal productivity loss, you can evaluate a process or product’s performance in real time.

By optimizing Digital Twin, performing preventive maintenance tasks can lower maintenance costs. Using real information can also be used to improve and optimize production operations. The digital twin is a fantastic tool that enables you to imitate behaviors and lower risks while testing new technologies online.

Additionally, they let you optimize the actions and states that take place while monitoring activities in real-time. With minimal productivity loss, you can evaluate a process or product’s performance in real time.

The digital twin city

Nearly 20 years in development, digital twin technology is used not only in the manufacturing industry but also in many other industries and in public life. The concept of the digital twin city, a new model of urban development and management based on digital twin technology, is gradually becoming clearer.

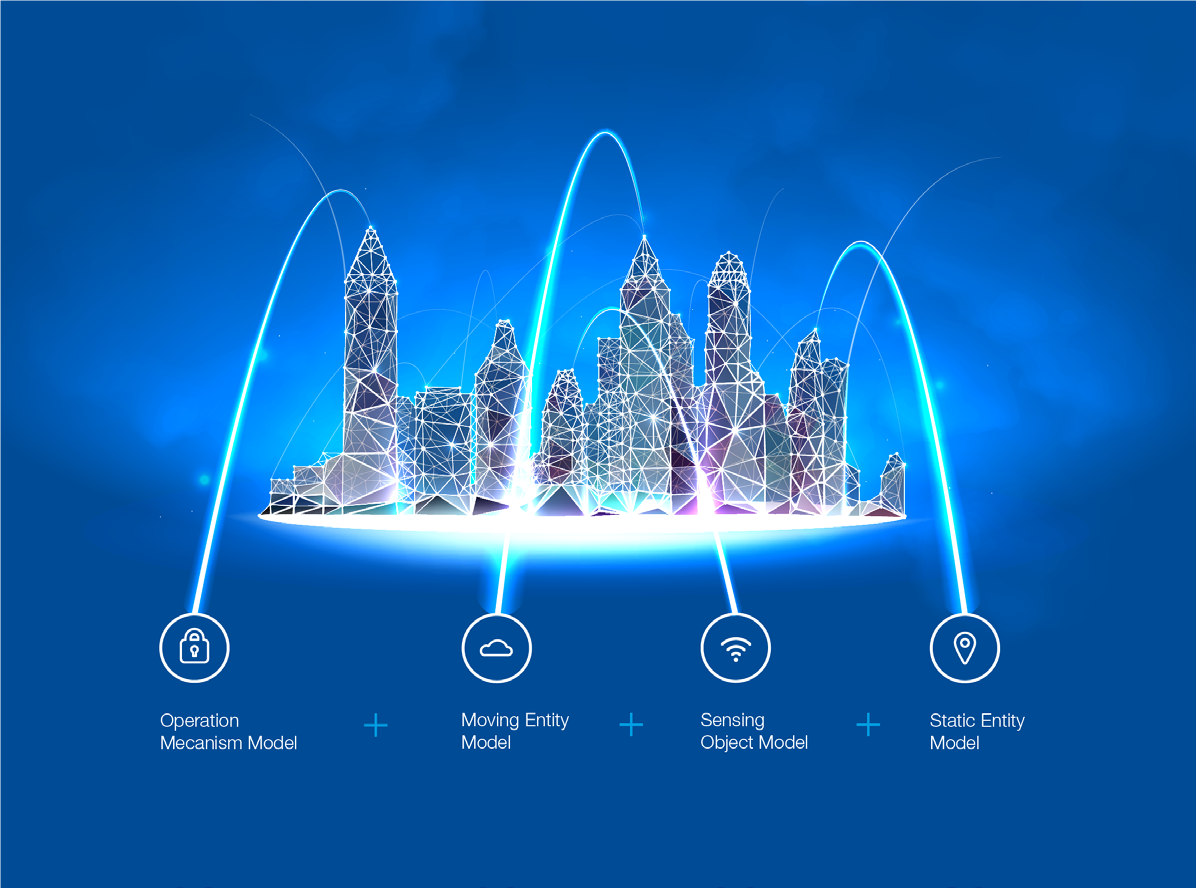

Precise mapping of the physical and digital city.

Through the use of technologies and techniques such as IoT technology, geographic information system (GIS) and building information modelling (BIM), the digital twin city can present a full picture of physical city operations in multiple layers and scales, including static geographical entities such as buildings, roads, vegetation, water systems, urban components and pipelines, as well as transitory elements such as people, vehicles, devices and organizations.

A promising future for digital twin cities

The global digital twin market is booming. It is predicted that by 2030, the application of digital twin technology will save $280 billion for urban planning, construction and operations. In terms of market size, the digital twin market is expected to reach $48.2 billion by 2026 and grow at a 58% CAGR (compound annual growth rate)

Precise mapping of the physical and digital city.

Through the use of technologies and techniques such as IoT technology, geographic information system (GIS) and building information modelling (BIM), the digital twin city can present a full picture of physical city operations in multiple layers and scales, including static geographical entities such as buildings, roads, vegetation, water systems, urban components and pipelines, as well as transitory elements such as people, vehicles, devices and organizations.

A promising future for digital twin cities

The global digital twin market is booming. It is predicted that by 2030, the application of digital twin technology will save $280 billion for urban planning, construction and operations. In terms of market size, the digital twin market is expected to reach $48.2 billion by 2026 and grow at a 58% CAGR (compound annual growth rate)

CONTACT INFO

- Address: MIddle East Commercial Centre Office #40, FIfth Floor Madinat AL Umal, Al Khobar Kingdom of Saudi Arbia.

- E-mail: info@sintechs.com